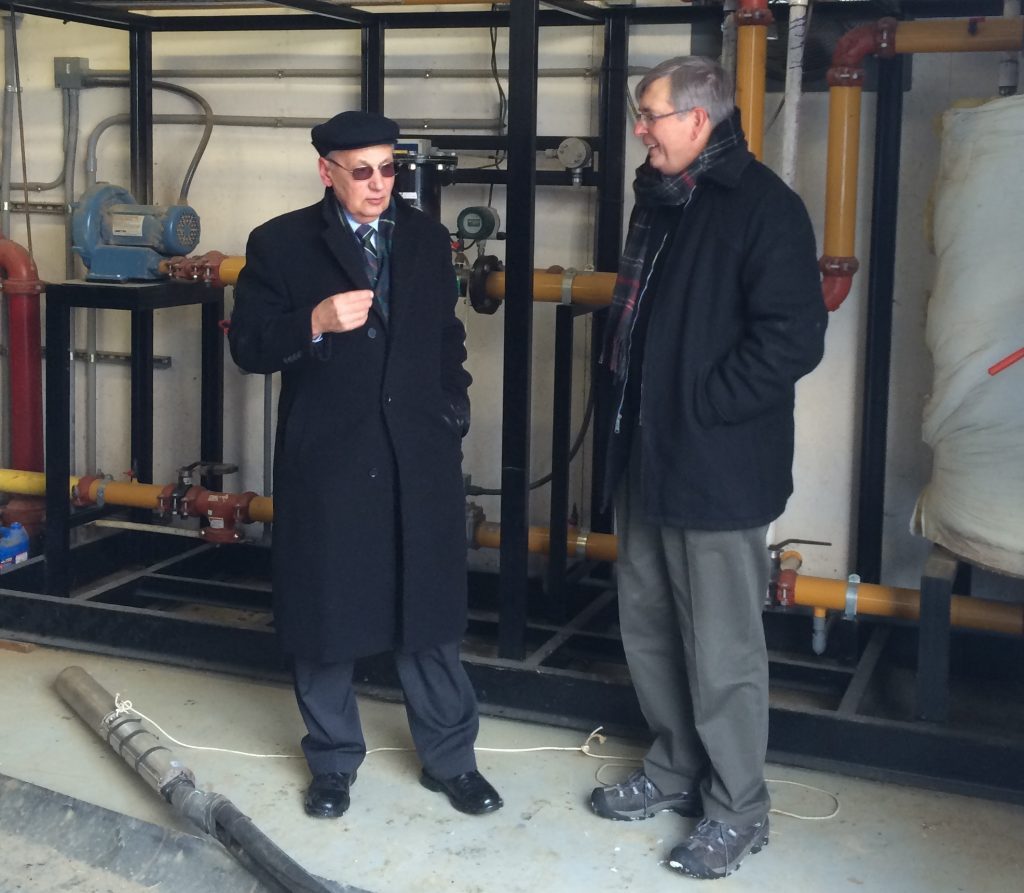

Agricultural Digesters LLC is our sister company dedicated to developing renewable electricity and natural gas at farms internationally.

Recently our industry focus has been renewable energy. More specifically a process less well known than wind and solar and that is – anaerobic digestion or biogas. This is a technology that converts manure from cows, pigs and chickens as well as food waste into electricity or natural gas. While doing this it also eliminates the green house gases, methane and carbon dioxide, that cause global warming.

Every anaerobic digestion project (biogas) is unique and the farmer or developer must determine which revenue streams can bring the greatest benefit. Depending on the market:

- Electricity or natural gas can be produced and used by the farm – the excess sold to the grid.

- Significant “tipping” fees can be collected from waste haulers.

- The separated solid output from dairy digesters, can be used as animal bedding or sold to nurseries.

- Pathogen reduction means less air, soil and water pollution as well as avoidance of fines.

- Combined heat and power generators run 24/7 and providing reliable electricity and heat where energy is not dependable.

- Generated carbon credits can be sold and renewable energy credits are tradable commodities.

- Our sister company, Agricultural Digesters LLC, can show farmers and investors the path to maximum profit. Here is a short video explaining some of what is required.

There are regional factors driving biogas development. For example:

- Several American states have established limits on incinerating food waste which can become a potent digester feedstock.

- Pig waste is an environmental issue in Europe and Russian speaking countries. Farmers face government fines if their manure management is unsatisfactory.

- The value of renewable natural gas (RNG) is skyrocketing. Upgrading biogas into RNG increases profits.

- Dependence on the world’s largest oil and natural gas suppliers is a political liability for many countries. Biogas is one solution.

- The price paid for biogas, the green tariff, varies from country to country and state to state.